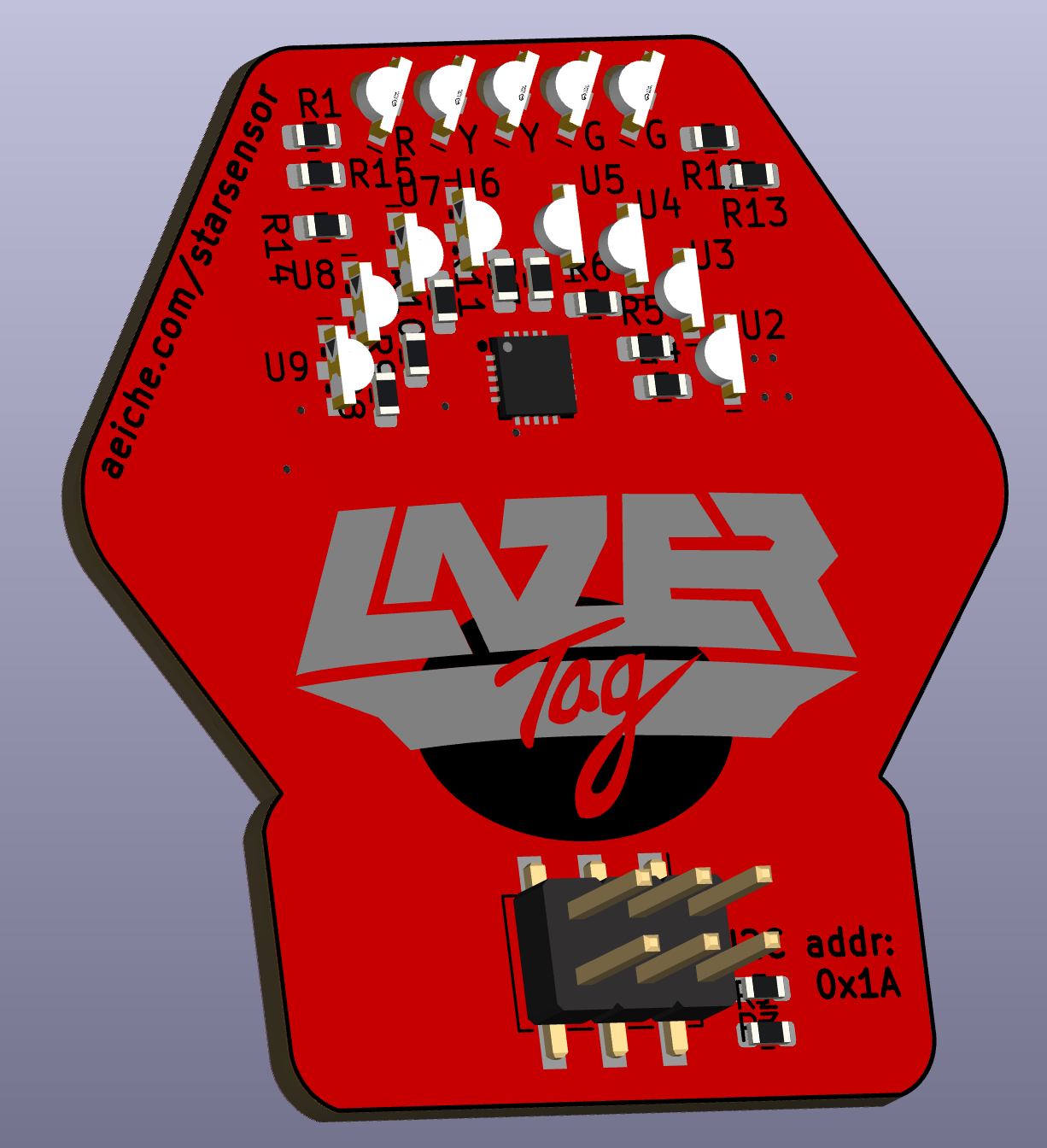

I was looking through old LazerTag pictures, and came across a decent version of the logo:

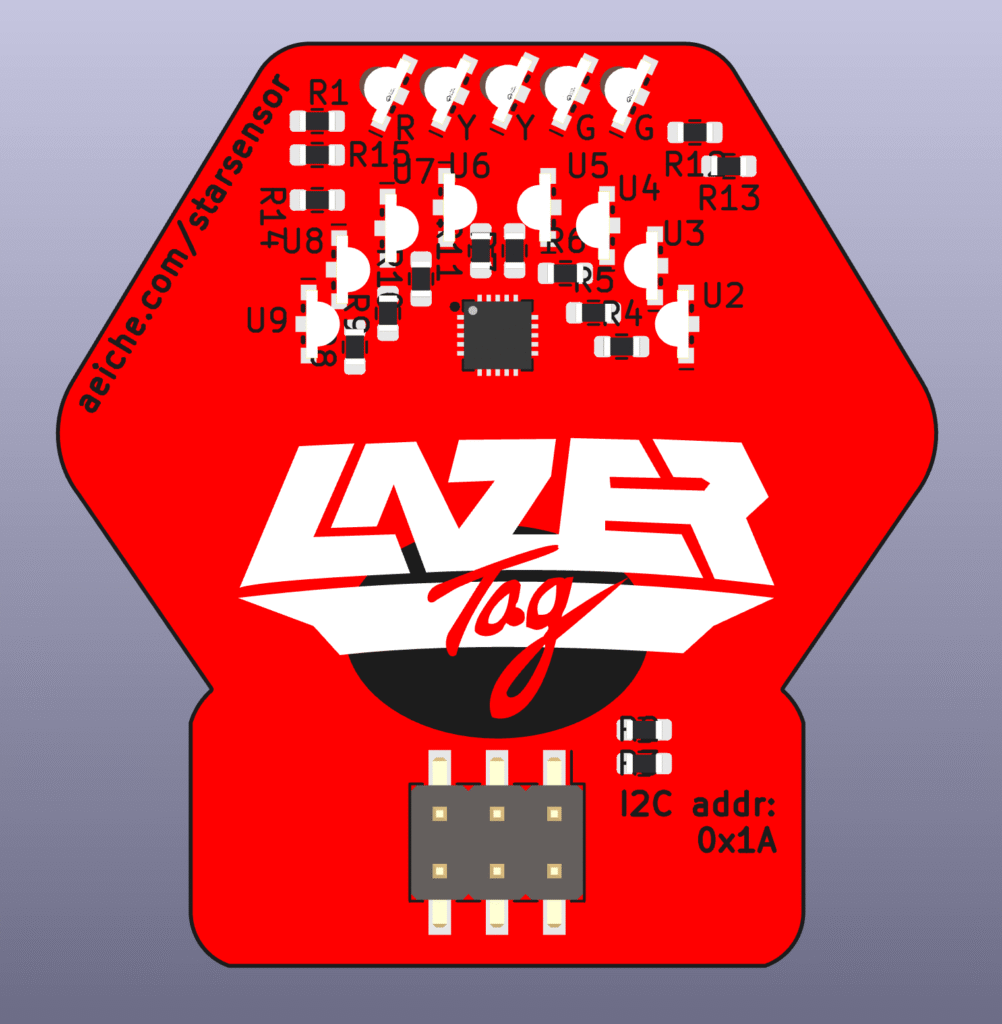

Staring at it for just a moment, I was kind of struck by how easy* it would be to put that on the back of the StarSensor. I have all the colors, and the HASL finish would even give it the right sort of shine. And because I’d just gone through a whole host of problem solving with getting shapes out of Inkscape, I figured I should give it a shot.

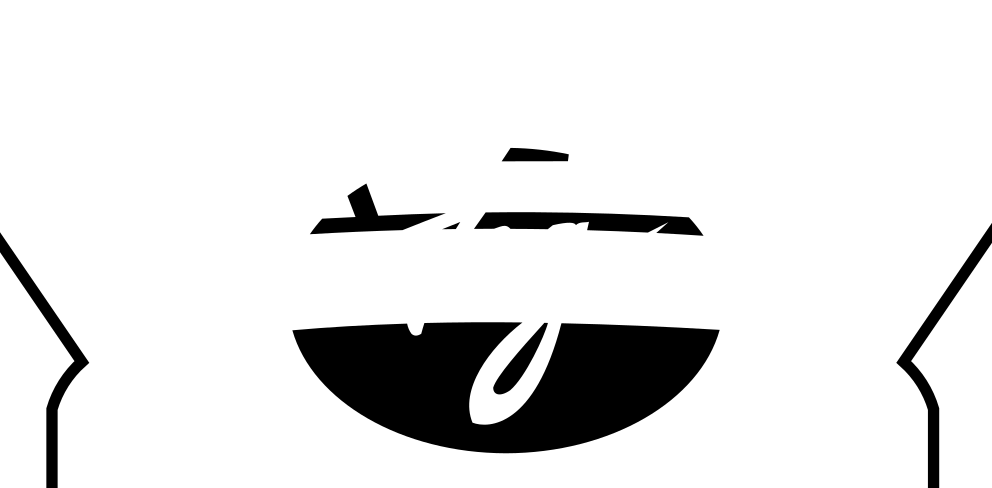

One of the tricks of working through the logo was thinking in negative space. I’m not trying to draw something here, I’m trying to draw something everywhere but there. The “Tag” part of the logo is challenging because the black “behind” it is actually black silkscreen that’s printed in just the negative space.

Starting with all the shapes I’d traced, lay them out how you want.

We’re going to ignore the “Tag” part for a moment. We need to remove the “Lazer” and Underline from the circle.

Now we remove “Tag” from “Lazer

And likewise, we remove “Tag” from the circle.

And now we have our finished layers: Black will prevent the soldermask , blue will be silkscreen, and the white negative space will allow the soldermask to show through:

I didn’t mention this, but you need to flip these things around if you want to put them on the back. Unlike components, you can’t just import an image and flip it in KiCad.

Routing in a limited space

I had started developing electronics for everything on my breadboard, and almost immediately ran into a problem. It turns out one of the pins I thought I could use for GPIO is reserved for use if you’re using SWDIO programming. So I had to tear up some of the electrical design anyway.

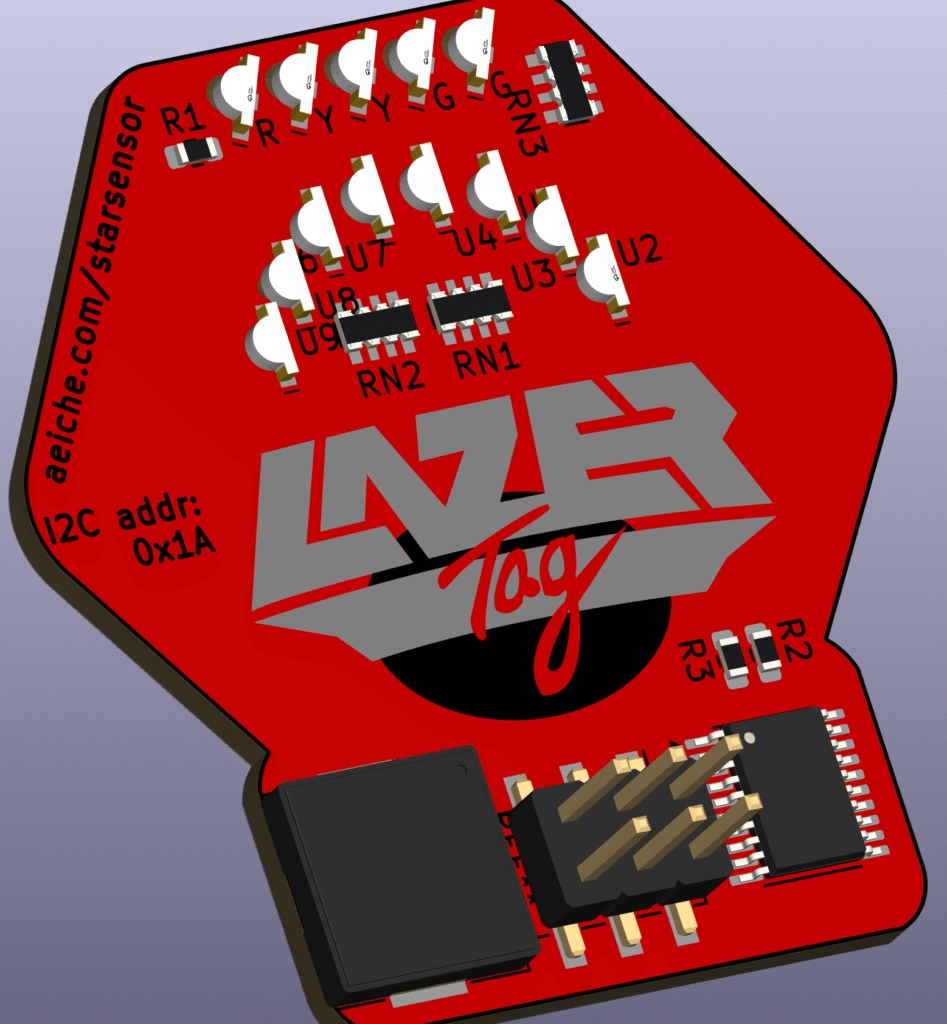

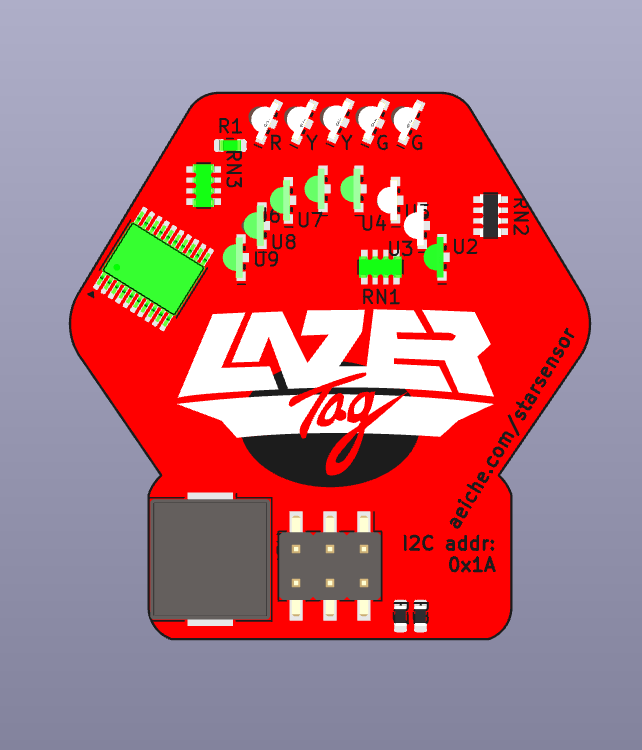

At the moment, I’m working through solutions. The board on the right here is the most recent version, swapping out the TSSOP for the QFN chip. I’ve had mixed success with flowing QFNs in the past so we’ll see if I regret that one. With the logo in place, the TSSOP was just too much of a pain. A few well placed vias have made routing the whole thing possible. It’s almost done.

I had kind of hoped to use serial RGB LEDs – it would have made the routing process a LOT easier, and probably made the programming a little easier.

Beautiful!

The biggest question mark with be how this gets handled in the manufacturing process. There are a lot of sharp curves and small features.